Causes Of Plaster Crack In Wall

What Causes Plaster Wall Cracks.. Older homes, especially, were constructed with lath and plaster interior walls, compared to the drywall often used today. The lath.

Drywall Cracks Cause prevention of cracks or ridging in plasterboard or gypsum board ceilings walls.

Repairing Historic Flat Plaster Walls and Ceilings. Mary Lee MacDonald. Historical Background; Common Plaster Problems; Repairing Historic Plaster; When Damaged.

Oct 04, 2012 Render work by the plaster professionals. What causes stucco to buckle, how to repair buckling stucco, why does stucco buckle. fix buckling stucco.

Loose plaster can be fixed without tearing it out and replacing it with new plaster or drywall. This article walks through the steps to a perfectly repaired plaster wall.

2 most essential requirements for successful plaster. Bond is obtained through mechanical bond, as on lath, or adhesion caused by the crystalline structure in the.

DRYWALL CRACKS - CONTENTS: what are the causes of drywall or gypsum board cracking in ceilings walls. Plasterboard or gypsum board crack prevention. Where, when why does drywall crack. Coefficients of thermal and moisture expansion contraction or movement for gypsum board products.

POST a QUESTION or READ FAQs about plasterboard cracks, drywall cracks, gypsum board cracking movement

REFERENCES

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Drywall cracks in ceilings or walls:

This article describes the common causes of all types of cracks that appear in drywall or gypsum board or plasterboard walls ceilings in building interiors. Illustrations show where cracks are most likely to appear, explain why, and suggest both repair approaches to drywall cracks and how to prevent cracking in plasterboard or gypsum board.

Photo at page top: severe settlement cracks around windows in an Alaskan home. Soil, foundation, and frost problems were causing severe ongoing movement in this structure.

Green links show where you are. Copyright 2015 InspectApedia.com, All Rights Reserved.

Causes Types of Cracks in Drywall, Plasterboard, Gypsum Board Walls Ceilings

Article contents - Causes of drywall or gypsum board cracking, sorted by categories

Gypsum Board Installation Error contribution to gypsum board cracks damage

Drywall installation snafus: poor support or connections, over-cuts with a drywall knife at corners of openings, failure to provide for seasonal or other variations in temperature moisture, improper joint finishing, possibly omission of drywall tape at some gaps, cracks, or repairs.

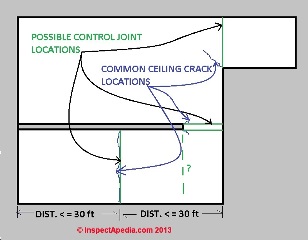

Drywall movement control joints omitted on long drywall runs in ceilings sketch at left or walls, distances over 30 ft. Control joints may also be needed at common ceiling or wall stress points such as at L, T, U or I shape ceiling or wall intersections like those shown in our sketch above.

See DRYWALL CONTROL JOINTS

Click to enlarge and show detail for any image

Drywall tape type used for corners: do not use mesh type drywall tape in building corners nor at ceiling/wall joints. It may be easier to install than paper tape but it is not as strong and is more tear-prone.

Long runs of continuous drywall, especially if more than 30 feet or about 10 meters in its long dimension are likely to suffer expansion/contraction cracking and possibly ridging if control joints are omitted.

Our drywall ceiling photographs above show a continuous ceiling that runs the length of this home, or 64 1/2 feet in total distance. The ceiling width is interrupted near one end by the distant partition wall you can see in the left hand photo, but the ceiling continues to open up into another room at that end of the house.

The ceiling crack shown in our photograph at above right occurs almost in the center of this long ceiling run. Seasonally as temperatures and humidity vary the width of this ceiling crack also changes from close to hairline warm humid summer months to nearly 1/8 in width cold dry winter months.

Using the coefficients of thermal and moisture expansion and contraction in drywall found

at PLASTERBOARD COEFFICIENTS, and with a ballpark estimate of seasonal temperature variation of 20 degrees and relative humidity variation of 30, we calculate that the total expansion or contraction range force over this ceiling length 744 inches is about 0.138 thermal and 0.145 moisture for a total of about 0.28 or 3/10 of an inch - more than a quarter of an inch - more than enough to cause a huge ceiling crack.

Why do we see that the actual ceiling crack is not nearly this wide. Because the 744 inch long ceiling is not unrestrained while the coefficients of thermal and humidity expansion and shrinkage are for unrestrained gypsum board. This ceiling s gypsum board is nailed to the underside of flat roof rafters spaced 16 o.c., distributing much of the thermal and humidity-related expansion and contraction forces over a large area.

Still we see an ugly wintertime crack in this ceiling and a noticeable summertime crack as well. There is not much point in just taping over this crack without installing control joints in this ceiling.

Metal corner beads are more crack and separation prone in drywall installations than plastic tape-on or glue-on using spray adhesive or mud-on corner bead material.

Building foundation settlement, frost heave, foundation drainage contributions to gypsum board cracks damage

Frost heaving foundations can cause differential movement in building walls that causes severe tearing or cracking in plasterboard, gypsum board, or drywall.

Photo above left: shear cracking shows up at the inside drywall corner of two exterior walls of a New York building. This cracking was caused by differential frost heaving. At above right you can see the corresponding crack in masonry block foundation supporting the building walls. High soil water content, drainage difficulties, and freezing climate explain this damage.

See FOUNDATION CRACKS DAMAGE GUIDE

Building framing shrinkage framing quality contribution to gypsum board cracks damage

Framing shrinkage other snafus: using wet lumber, pressure treated and still wet lumber, or poor quality framing connections that permit movement and settlement that can in turn lead to drywall cracks, tears, or drywall joint tape separation.

In a demonstration that the ceiling crack stress point sketch is not just theory, our photos just above show cracks at the taped intersection of ceiling to partition wall at a natural stress point. This crack appeared in less than a year after new construction. The underlying cause may have been a combination of framing shrinkage and slight sagging of the supporting floor structure.

The wall corner projecting into the room is directly above a stairwell cutout. Floor settlement actually pulled this corner down, separating it from a rigid I-beam roof structure.

We will repair this crack by cutting out the separated paper drywall tape and re-taping the joint on both sides of the partition wall corner-to-ceiling juncture. But this little repair is a bit of trouble as re-painting the ceiling and wall will also be needed. In my OPINION DF this is normal new construction cracking that is difficult to prevent.

Our photo at left shows the original drywall being installed on the same ceiling as in the drywall tape joint separation photographs above.

You can see that the sheetrockers took care to hang a full piece of drywall that extended past the partition wall corner precisely because they knew that this was a stress point. That detail worked - we did not see a tear in the drywall itself. What did ensue was enough downwards movement to stress and open the drywall tape at the partition wall-to-ceiling joint.

Below is a second example of a similar effect. Here we see a complex soffit structure carrying windows and suspended from a conventionally-framed 2x12 ceiling structure. Here, too, cracks appeared in the ceiling as the structure below moved downwards. Click to enlarge the photo at left to see this drywall ceiling crack in more detail.

Framing flexing - drywall cracks: in interior ceilings or cathedral-ceilings not framed to modern construction standards for stiffness we may see cracks, often at drywall joints, caused by flexing in the ceiling structure.

Particularly in some older homes with minimal attic floor framing that was originally intended only to support the weight of a plaster ceiling, we may see ceiling cracks caused by building occupants or home inspectors who clambered around in the attic area above, stepping on framing members never intended to bear their weight.

Framing bowed, bent, uneven: installing drywall or gypsum board across uneven surfaces due to inconsistent or sloppy framing can add to material stresses that ultimately show up as plasterboard cracks.

Such cracks are most likely to appear when a side joint or end butt joint appear over or close to a framing variation extremity.

Use furring, cutting, trimming or similar measures to flatten out the install surface and to minimize these stresses, and avoid placing a taped joint over stress points.

Framing over-spanned: drywall installed at right angles to the supporting framing can span 24 1/2 or 5/8 thick drywall on walls, but on ceilings 1/2-inch or 5/8-inch drywall can span

24 inches only if it is installed perpendicular to the joists

and supports less than 1.3 pounds per square foot psf of

insulation.

Otherwise, 16-inch on-center spacing is recommended.

With latex spray textures or airless spraying of

latex paints, perpendicular installation over 16-inch on center

framing is recommended to prevent sagging. - S. Bliss, Best Drywall Practices

Roof truss uplift: arching roof or floor trusses caused by moisture/temperature differences between truss upper lower members. The truss uplift problem is less likely to occur in an interior ceiling supporting a floor above because both sides of the ceiling/floor structure are within conditioned space, making for more uniform temperatures and moisture levels across the truss.

See TRUSS UPLIFT, ROOF for details.

Moisture or relative humidity variation contribution to gypsum board cracks damage

Moisture or humidity variation: significant changes in the building moisture level or thus in the moisture content of plasterboard or gypsum board can cause expansion or shrinkage sufficient to produce a 1/16 wide or larger crack even if other forces are not in play.

Details of the coefficients of thermal expansion or contraction and the coefficients of moisture-related expansion and shrinkage of plasterboard are

at PLASTERBOARD COEFFICIENTS.

Structure or Foundation Settlement contribution to gypsum board cracks damage

Settlement in buildings causes plasterboard cracks tears: for any reason: framing shrinkage, foundation damage, site drainage problems, earthquake movement or slab settlement can cause significant gypsum board damage. Below we give several examples of types of building movement traced to settlement and causing significant interior wall or ceiling cracking.

Backfill settlement in New York: the photographs below illustrate severe settlement in a New York home. Unlike the Alaskan house above damaged by construction on thawing permafrost, the home below had been constructed on backfill over a stream bed.

Seasonal water flowing below the building appears to have contributed to severe slab and foundation damage that telegraphed upwards through this home as floor-wall separation, ceiling-wall separation, and cracks at windows and doors of the home shows in the photos just above.

By noting the plasterboard crack locations, patterns, angles, and dimensions it was apparent that they all pointed to settlement in the supporting slab.

Checking the finished basement floor for level we confirmed that the floor was settling significantly towards the building center.

Permafrost settlement in Alaska: The two photographs above show severe plasterboard cracking in the same Alaskan home illustrated at the top of this page. In the left photo settlement and drywall tearing cracks appeared at a horizontal drywall joint to the right of a door jamb a poor location for a drywall joint and exacerbated by the use of mesh tape that is not as strong or tear resistant as paper tape.

Click to enlarge and see detail for any image

In the right hand photo above we see a typical diagonal gypsum board crack extending down and to the left of a window opening. The window trim has been pulled apart as well. These cracks are not to be blamed on the drywall installation: this home had suffered movement in excess of what plasterboard is expected to endure. This building is discussed in more detail

at SINKING BUILDINGS.

Earthquake damage to walls in California:

Earthquake damage crack patterns characteristic of the Northridge earthquake in California in January 1994 are illustrated by our photo shown at left.

This crack pattern appears here in a stucco exterior, but it was duplicated on drywall interiors as well.

Buildings suffering this extent of damage require structural repair or possibly replacement.

Details are at EARTHQUAKE DAMAGED FOUNDATIONS.

Temperature variation contribution to gypsum board cracks damage

Temperature variation: significant changes in the building interior temperature or thus in the temperature of plasterboard or gypsum board can cause expansion or shrinkage sufficient to produce a 1/16 wide or larger crack even if other forces are not in play. Even if building temperatures are kept steady after construction is complete, drywall installation temperatures may contribute to subsequent cracks: mudding drywall in cold buildings increases drying times and may increase the crack risk.

Large variations in building temperature or moisture level or both. For example, leaving a building un-heated in a freezing climate or turning off air conditioning dehumidification in a wet or humid climate.

See HUMIDITY CONTROL TARGETS INDOORS

and also DRYWALL MOLD TESTING.

Details are at PLASTERBOARD COEFFICIENTS.

How to Prevent Drywall Cracks at Drywall Side or End Butt Joints

Use kiln-dried lumber for framing walls and ceilings. As Steve Bliss points out at DRYWALL INSTALLATION Best Practices, With wet or poor-quality framing, there are

bound to be problems in the drywall finish. With dry

lumber and proper detailing, however, drywall problems

can be kept to a minimum.

Use drywall screws instead of drywall nails. Set the screws just below the drywall paper surface but not so deep as to cut through the paper.

When hanging drywall on a ceiling supported by the lower chord of roof trusses, review the suggestions at TRUSS UPLIFT, ROOF, including using clips rather than screws or nails to secure drywall within a few feet of either side of building center partitions that run at right angles to the lower chord of the roof trusses.

The floating drywall corner method described at INTERIOR FINISHES: BEST PRACTICES can also be used to float the ceiling drywall over the center partitions.

Inside corners at walls and between

walls and ceilings are stress points for drywall and common

places for cracks or nail pops. Leaving one side of the

joint free to move without fasteners will eliminate most of

these problems.

On ceilings, place the first screws 7 to 12 inches in

from the corner and support the ceiling drywall with the

wall panels. Also, do not fasten the top 8 inches of the wall

panels.

No screws should go into the top plate, where

shrinkage may occur. Similarly, leave one side unfastened

at wall-to-wall corners, but make sure it rests against solid

wood backing or drywall clips see Figure 5-1.

Prevent Drywall Cracks Caused by roof truss or on occasion floor truss uplift

Nail pops found in some building ceilings and actual tears or cracks at the wall/ceiling juncture at building walls located under the center of certain roof trusses when moisture temperature differences between the truss bottom chord and upper members cause the truss to arch.

Details and more illustrations of the roof truss uplift problem more steps to prevent drywall cracking nail pops are found at

TRUSS UPLIFT, ROOF

The drawings of roof truss uplift and corrective measures for truss uplift shown here are provided courtesy of Carson Dunlop Associates and appears in their Illustrated Home.

Also see CEILING FINISHES INTERIOR and see Best Interior Finish Practices.

GRC: Gypsum Board Joint Ridging Cracking

Drywall / Gypsum Board / Plasterboard Butt-Joint Ridging Causes Prevention

As this article series discusses the expansion and shrinkage effects of drywall or gypsum board ceilings and walls plasterboard in the U.K., Australia, New Zealand and other countries, we include this description of cosmetic damage caused by expansion rather than material shrinkage stresses. GRC or gypsum ridging and cracking has been reported world-wide, with most writers commenting from Australia, Canada, New Zealand, the U.K. and the U.S. 1 2 4

Click to enlarge any image

The Gypsum Association s definition of ridging is

Joint ridging, also called beading, is a uniform, fine

line deformation occurring at gypsum board joints. It is

usually caused by compression of the edges or ends of

the finished and decorated gypsum board resulting

from the edges or ends being forced together from exposure to alternating periods of high and low

temperature and humidity extremes due to thermal or hygrometric expansion. - 10 Repair of Gypsum Board

Joint Ridging

GA-221-00

Note: both ridging and cracking in gypsum board may both appear in the same installation. For example, ridging may appear when forces thermal expansion, moisture expansion cause the material to expand, while cracks or tears may appear in plasterboard or gypsum board when the opposite site conditions cooler temperatures and more dry conditions cause gypsum board to contract.

OPINION: As we note below, many experts opine that the dominant forces in drywall cracking or tears are probably framing shrinkage and building movement - a view with which I agree. However gypsum board joint ridging is almost certainly going to be due only to expansion forces alone and would be expected to appear particularly at long runs of unrelieved no control joints drywall exposed to high moisture and high temperature or the two combined.

Suggestions for preventing gypsum board ridging include:

Inspect, document and correct building framing defects such as gaps, poor nailing or open framing joints before hanging the drywall.

Do not hang gypsum board on wet or pressure treated framed ceilings or walls without special design provisions such as the use of resilient channel supports.

Inspect, document, and correct site drainage, footing drain defects, building leaks and other sources of abnormal building moisture or of abnormal building movement, settlement, framing shrinkage.

Manage building gypsum board humidity and temperature: Document the building humidity and temperature at the time of drywall application and we recommend documenting as well the actual temperature and humidity level or moisture level of the drywall product being installed, and document abnormal variations in building temperature and humidity indoors beyond its design parameters. Gypsum board should be allowed to reach temperature and humidity consistent with the building interior where it is to be installed before it is hung or applied.

Additional measures to avoid ridging may include back-blocking or supporting at butt joints extra cost, rarely used - DF

Repair recurrent problem areas by supporting drywall on resilient channels

Use control joints at problem or stress points and in areas of drywall extending beyond 30 feet of unbroken or unrelieved panels.

See the SBCA s detailed recommendations at Gypsum Joint Ridging and Cracking 1

Continue reading at DRYWALL CONTROL JOINTS or select a topic from the More Reading links or topic ARTICLE INDEX shown below.

Or see PLASTERBOARD COEFFICIENTS

Suggested citation for this web page

DRYWALL CRACKS at InspectApedia.com - online encyclopedia of building environmental inspection, testing, diagnosis, repair, problem prevention advice.

More Reading

Green link shows where you are in this article series.

CEILING FINISHES INTERIOR

CEILINGS, DROP or SUSPENDED PANEL

CEILINGS WALLS, PLASTER TYPES

CEILING TILES ASBESTOS CONTENT

CHINESE DRYWALL HAZARDS

DRYWALL CONTROL JOINTS

DRYWALL CRACKS

DRYWALL FINISH LEVELS

DRYWALL INSTALLATION Best Practices

DRYWALL MOLD RESISTANT

DRYWALL NAIL POPS

DRYWALL, PLASTER, BEAVERBOARD

EARTHQUAKE DAMAGED FOUNDATIONS

LINCRUSTA CEILINGS WALLS

METAL CEILINGS ALUMINUM TIN

PLASTER TYPES METHODS in BUILDINGS

PLASTER BULGES PILLOWS

PLASTER LATH, METAL

PLASTER, LOOSE FALL HAZARDS

PLASTER TYPE IDENTIFICATION

PLASTERBOARD COEFFICIENTS

SINKING BUILDINGS

STAIN DIAGNOSIS on BUILDING INTERIORS

TRIM, INTERIOR

WALL FINISHES INTERIOR

FAQs below discusses field reports of problems solutions for this topic

Frequently Asked Questions FAQs

Click to Show or Hide FAQs

Ask a Question or Search InspectApedia

Use the Click to Show or Hide FAQs link just above to see recently-posted questions, comments, replies, try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Technical Reviewers References

Publisher s Google Page by Daniel Friedman

Click to Show or Hide Citations References

Support InspectApedia.com See Fewer Advertisements

From Google s Contributor website: Contribute a few dollars each month. See fewer ads. The money you contribute helps fund the sites you visit.

How to Repair a Crack in a Plaster Wall. Cracks in plaster walls can be troublesome and frustrating to repair. This is because once a plaster wall cracks, it will.